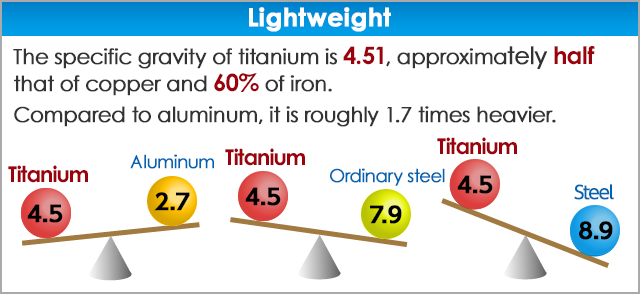

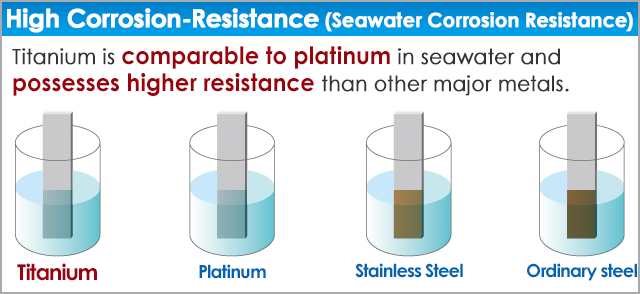

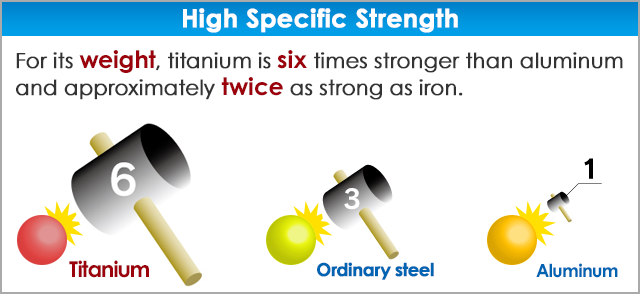

Lightweight, High Specific Strength, and High Corrosion-Resistance

Japanese technology helping lives. Titanium’s biocompatible and non-magnetic properties make it an indispensable material primarily used for implants in the medical field.

Outside of the medical field, the light, strong, and rust-resistant properties make titanium compatible for application in severe environments as an essential material in advanced technology.

Moreover, the metal can be anodized to add color and is utilized for accessories such as wrist watches and earrings.

Application

Artificial joints, artificial dental roots, bone fracture fixation, surgical instruments, catheters, and various other medical products,

aircrafts, chemical plants, heat exchangers, golf clubs, earrings, stationery

![Implants [Artificial joints, dental roots]](https://www.sakuma-ss.co.jp/wp/wp-content/uploads/2017/07/steel_18_002_07_fix.png)

Implants

[Artificial joints, dental roots]

Medical equipment

Anodization

* The above products have been cited and reprinted with permission from Aomi Precision Co., Ltd.

Main alloys

| JIS (Equivalent Product) | ASTM | DIN | AMS | Descriptions | |

| Industrial Use | Medical Use | ||||

| Class 1 (DT1) | Grade 1 | F67 Grade 1 | 3.7025 | Pure titanium for industrial application. Excellent corrosion-resistance with especially high resistance to seawater corrosion. Used for chemical processing equipment, oil refinery equipment, pulp and paper industrial equipment, etc. |

|

| Class 2 (DT2) | Grade 2 | F67 Grade 2 | 3.7035 | ||

| Class 3 (DT3) | Grade 3 | F67 Grade 3 | 3.7055 | ||

| Class 4 (DT4) | Grade 4 | F67 Grade 4 | 3.7065 | ||

| Class 60 (DAT5) | Grade 5 | - | 3.7164 | 4928 | α-βalloy. [Ti-6Al-4V] High-strength with excellent corrosion-resistance. Used for structural materials in the chemical industry, machinery industry, and transportation equipment (such as large steam turbine blades, marine propellers, automotive components, etc.). |

| Class 60E (DAT5E) | - | F136 | 4930 | α-βalloy. [Ti-6Al-4V ELI] *1 High-strength with excellent corrosion-resistance. Retains toughness down to extremely low temperatures. Used for structural materials used in extremely low temperatures (ship hulls in manned deep-sea exploration vessels, liquid nitrogen storage, etc.) and medical materials. |

|

| Class 61 (DAT52) | Grade 9 | - | α-βalloy. [Ti-3Al-2.5V] Medium-strength with excellent corrosion-resistance, weldability, moldability, and cold workability. Used for medical materials and leisure products. |

||

| Class 61F (DAT52F) | - | - | α-βalloy. [Ti-3Al-2.5V with good machinability] Medium-strength with excellent corrosion-resistance, hot workability, and machinability. Used for automobile engine connecting rods, shift knobs, nuts, etc. |

||

| Class 80 (DAT51) | - | - | βalloy. [Ti-4Al-22V] High-strength with excellent corrosion-resistance and plasticity under normal temperatures. Used for automobile engine retainers, golf club heads, etc. |

||

*1 ELI stands for Extra Low Interstitial Elements (Contains specifically reduced levels of oxygen, nitrogen, hydrogen, and iron.)

DAT is a registered trademark of Daido Steel Co., Ltd.

Please contact us for other available titanium and titanium alloys not listed above.

Material Properties