Reduce the overall cost of component manufacturing through Sakuma’s supply chain!

Automobile Components

High quality and precision are required in automobile components.

Sakuma Special Steel provides outstanding material knowledge and optimum processing methods.

Progressive die press

Machining

Cold working + Machining

Cold working + Machining + Polishing

Pressing + Machining

Processing Capabilities

| Processing Fields | Processable Sizes | Press Capacity | Measurements and Configuration | |

|---|---|---|---|---|

| Cold Forging (Parts Former) | Φ2–Φ23 | 25t–100t | Stainless steel | SUSXM7, 303, 304, 430, 440C |

| Structural steel | SWCH, SCr, SCM | |||

| Other | Ni alloy, Kovar, copper, aluminum | |||

| Cold Forging (Vertical Press) | Φ10–Φ50 | 160t–600t | Stainless steel | SUSXM7, 303, 304, 430, 440C |

| Structural steel | S-C, SCr, SCM | |||

| Other | SUJ, SKD | |||

| Φ20< | 160t–1500t | Structural steel | S-C, SCr, SCM, SPCC, SPHC, SWCH | |

| Hot Forging | Φ30–Φ165 | 180t–1500t | Structural steel | S-C, SCr, SCM |

| Machining | Φ4–Φ32 | - | Stainless steel | SUSXM7, 303, 304, 310S, 440C, 430, 630 |

| Structural steel | S-C, SCr, SCM, SNCM, SUM | |||

| Other | Ni alloy, titanium, Kovar, copper aluminum, resin |

|||

| Progressive die press | 0.05–9.0mm (Thickness) | 30t–600t | Structural steel | SUS303, 304, 310S, 316, 410 SUS440C, 430, 405, 630 |

| Structural steel | SPCC, SPHC, SPCD, SPCE, SAPC, SECC | |||

| Other | Copper, aluminum, gold cladding | |||

Contact Information

| USA | : | Sakuma International America, Inc. |

| Thailand | : | Sakuma (Thailand) Co., Ltd. |

| Indonesia | : | PT Sakuma Indonesia |

| China | : | Sakuma Special Steel (Changzhou) Co., Ltd. |

| Japan | : | Sakuma Special Steel Co., Ltd. Toaki branch 81-8-52-689-7381 |

| : | Please click “Inquiry” button above. |

USA :

Sakuma International America, Inc.

Thailand :

Sakuma (Thailand) Co., Ltd.

Indonesia :

PT Sakuma Indonesia

China :

Sakuma Special Steel (Changzhou) Co., Ltd.

Japan :

Sakuma Special Steel Co., Ltd. Toaki branch 81-8-52-689-7381

E-mail :

Please click “Inquiry” button above.

Machine Tools and Other Processed Products

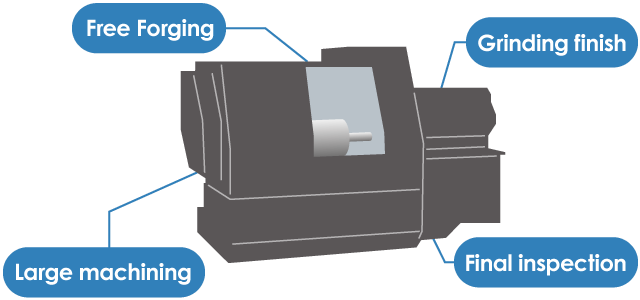

With the cooperation of our many partner companies, we provide consistent service until the final finishes.

We will handle any difficult processes.

Free Forging

- Process Flow

- Free Forging

- Features

- Improved yield achieved by our forging method. Applicable to up to 8,000-ton press.

Grinding finish

- Process Flow

- Free Forging–Heat treatment–Lathing–BTA–MC–Induction hardening–Grinding

- Features

- Grinding finish for gauge alignment of taper parts and fitting of bearings.

Large machining

- Process Flow

- Free Forging–Heat treatment–Lathing–BTA–Honing

- Features

- Large lathe machining and large-diameter BTA deep hole drilling

Final inspection

- Process Flow

- Final inspection

- Features

- Quality assurance is achieved by the use of roundness measuring instruments, surface texture and contour measuring instruments, coordinate measuring machines, etc.

Processing Capabilities

Machine Tool Spindles

Process Flow

Forging, heat treatment, lathing, BTA, MC, nitriding, induction hardening, polishing, honing

Compatibility

Compatible with spindles for large lathes up to 825 mm in diameter and 1400 mm in length

Features

High-precision deep hole drilling by BTA and gun drills.

Grinding finish for fitting taper parts and bearings

Quality assurance is achieved by the use of roundness measuring instruments, surface texture and contour measuring instruments, coordinate measuring machines, etc.

Real-time delivery management made possible by sharing production management systems with partnering companies.

Other Processed Products

Materials for Processing

Nickel alloys (INCONEL, HASTELLOY, etc.), titanium and titanium alloys, cobalt chrome, magnesium, CFRP, castings, iron-based metals, SUS, aluminum, copper

Processing Technology Examples

- ①Nickel alloy overlaying and plate work processing

- ②Ultra-thin materials processing with minimal distortion

- ③From micro drilling of holes 0.02 mm in diameter to extra-large five-face machining (Offering a broad spectrum of capabilities)

- ④Bore honing with submicron precision

- ⑤Large roll grinding of materials measuring 1,000 mm in diameter and 5,000 mm in length, precision surface grinding of materials measuring 3,050 x 800 mm, cylindrical grinding measuring 1,600 mm in diameter and 600 mm in length

- ⑥Super-precision jig grinding and surface grinding in temperature-controlled rooms